Mattapan Station

Description

Mattapan Station is a 165,000 sq.ft. multifamily development located in Mattapan, a neighborhood of Boston, MA. BEC is providing Passive House Consultant support services, as well as Quality Assurance Commissioning (QACx) on behalf of the Preservation of Affordable Housing (POAH). POAH is a nonprofit organization whose mission is to preserve, create, and sustain affordable, healthy homes that support economic security, racial equity, and access to opportunity for all. The project will provide commercial and community space to the Mattapan Square neighborhood as well as transit-oriented, mixed-income housing with 135 rental units.

Passive House Feasibility

BEC conducted a Passive House Feasibility Study to determine if the project can reasonably achieve the Passive House performance standards of the Passive House Institute US (PHIUS). BEC identified several changes to the building envelope specifications, enclosure performance, and ventilation system needed to reach the applicable Passive House criteria. Based on the findings of this feasibility study and on confidence in the project team, POAH decided to pursue Passive House certification.

Design Phase Support

Once POAH committed to Passive House certification, BEC launched into guiding the design team toward the Passive House goal. POAH and TAT, the architects, actively fostered an integrated design process that leveraged collaboration between all members of the project team. Serving as the pre-construction General Contractor, Dellbrook JKS readily grasped the concepts of airtightness and continuous insulation, and was able to contribute significantly to the development of details.

In the design phase, BEC identified issues within the enclosure and mechanical systems that did not conform to the performance goals and certification requirements. BEC provided rationale for possible solutions based on research, simulations, and decades of combined experience in high performance building projects.

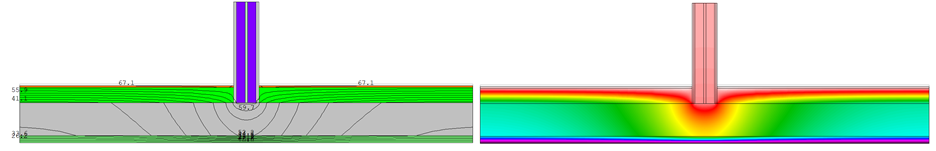

BEC developed detailed energy models to confirm the specifications needed. BEC analyzed the thermal enclosure assemblies and their penetrations to minimize risks. For example:

- The steel framing of a canopy penetrating the enclosure, which would create a thermal bridge and present challenges in controlling air leakage and condensation

- The roof system, which risked bellowing (from uplift pressures) which could, in turn, result in moisture accumulation

- The optimal vapor retarder to control cold weather condensation and allow diffusion drying

Additionally, BEC conducted a shading study using different configurations of shading device length, projection, and orientation, which affect occupant well-being and comfort as well as heating and cooling loads. BEC simulated each combination to analyze the resulting loads and energy consumption.

As the design for the project edged closer to its final form, BEC assembled the documentation needed to submit the project for as-designed “pre-certification”. BEC compiled documents to prove project features such as kitchen ventilation layouts and slab perimeter insulation. BEC also performed calculations, such as plumbing take-offs and condensation risk assessments. Iterative rounds of review by PHIUS and resubmission by BEC drew out increasing levels of detail and scrutiny. Finally, on September 15th, 2020, PHIUS awarded Passive House precertification to the Mattapan Station Redevelopment.

Construction Phase Support

After construction began, BEC continued to provide support by responding to RFIs, reviewing submittals, performing field inspections, and providing recommendations on construction methods.

For example, BEC observed multiple rounds of air and water leakage testing performed on mock-up window installations. Through these observations, BEC identified air and water leakage paths that had contributed to failures. BEC worked with TAT to develop revised window details to address the inherent leakage vulnerabilities revealed in the mock-up testing. BEC also recommended methods to the GC to help overcome challenges in the installation.

Several issues requiring input from BEC emerged during construction. At one portion of the building, interior partitions were designed to be framed on top of plywood resting on a thick layer of rigid insulation. Because of constructability and sequence constraints, Dellbrook asked if these non-bearing partitions could sit directly on the post tensioned slab, instead of on the plywood over insulation. BEC confirmed that the updated detail creates a thermal bridge, but also that the heat loss/gain would not jeopardize the Passive House performance targets and that there was little-to-no comfort or condensation risk.

Conclusion

The new construction project for Mattapan Station’s redevelopment pursued high performance targets to accomplish POAH’s goals of comfort, resilience, and economical viability. BEC’s assistance included the facilitation of Passive House precertification, design phase support to increase the building’s performance, and continued construction phase support to keep the project on track of POAH’s goals.